New product series FATH LEAN 4.0

Today, being competitive means lean management and production. Kanban, KVP and 5S are as established in medium-sized companies as Just-in-time production and Industry 4.0 approaches. FATH is no exception here. Which is why they are constantly perfecting the range of solutions for there customers. With the new FATH LEAN 4.0 products, for example. They combine well thought-out components with IoT technology. This enables manufacturers to optimize their material flow, reduce warehousing and produce more efficiently. The smart solutions will be available to view for the first time from 10 to 12 March at Logimat 2020 in Stuttgart.

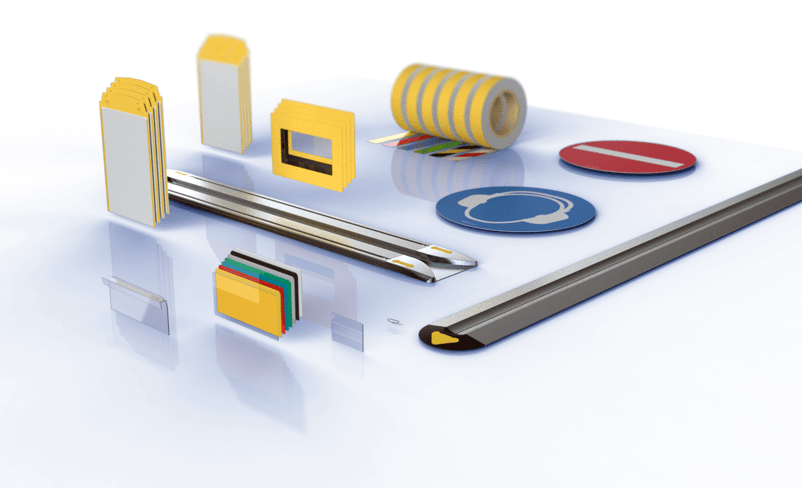

FATH LEAN 4.0 products: Labeling systems for production and logistics, information boards for controlling and monitoring, as well as complete material flow systems, enable more streamlined processes and more efficient use of existing resources. (Picture Source: FATH GmbH)

Germany – Spalt 25.02.2020 – What a year: At the company headquarters in Spalt, Middle Franconia, FATH built a new logistics center and invested heavily in new tools in 2019. And as if this wasn't enough, the company has also developed a new product portfolio that is now ready for the market. "LEAN 4.0" is the name – which also gives a strong indication of its application area. It is targeted toward manufacturing companies with modern shop floor management that are gradually digitalizing their production and logistics processes. "The networking of machines and intra logistics opens up incrediable opportunities for manufacturers", states Managing Director Wido Fath with conviction. "We are accompanying Industry 4.0 pioneers with tailored solutions."

The LEAN 4.0 product range includes visualization elements and products that optimize internal transport and material flow. You can integrate them seamlessly into existing processes. They compliment the FATH engineering components, but can also be used independently.

Whether labeling systems for production and logistics, information boards for controlling and monitoring, or complete material flow systems: The focus is always on more streamlined processes and more efficient use of existing resources. "Other companies ask what changes they could make in the meeting room", says Michael Honisch. "We go directly to where the action is." The head of LEAN 4.0 at FATH swears by the proximity to the users. His team watch over their shoulders while they carry out the actions, ask questions and listen carefully. This leads to ideas that are consistently focused on the process and user requirements and resulting products.

"We develop with a design thinking approach and operate with lean production ourselves", says Mirko Jan Fath. The Managing Director is convinced that this is the most important factor to ensure that the company develops in line with the needs of the market. "You can't offer added value to lean companies if you don't use the approach yourself". He states that some solutions were created because current products on the market did not meet the requirements for the company's own warehousing needs. Whether FATH replaces problematic materials or makes use of efficiency potential. For example with their holders for labels on shelves and containers made from 40% recycled PVC-free material that can be removed without residue and reused. An inconspicuous product improvement with a big impact: "Instead of going through the time-consuming process of removing adhesive residue and applying new label holders, the label is simply changed and you're done!", Fath explains, highlighting the time saving. "In addition, the label holders protect the environment and the procurement budget."

FATH is an international company group with headquarters in Spalt and around 330 employees all over the world. The company specializes in the development, production and sale of components for mechanical engineering. The group has sites in Germany, the USA, China, Hungary, Great Britain and the Netherlands (fath24.com).